Positioning systems for test stations

Precise over large working areas

The measurement of lenses, laser optics and other optical systems requires precise positioning over a large working range.

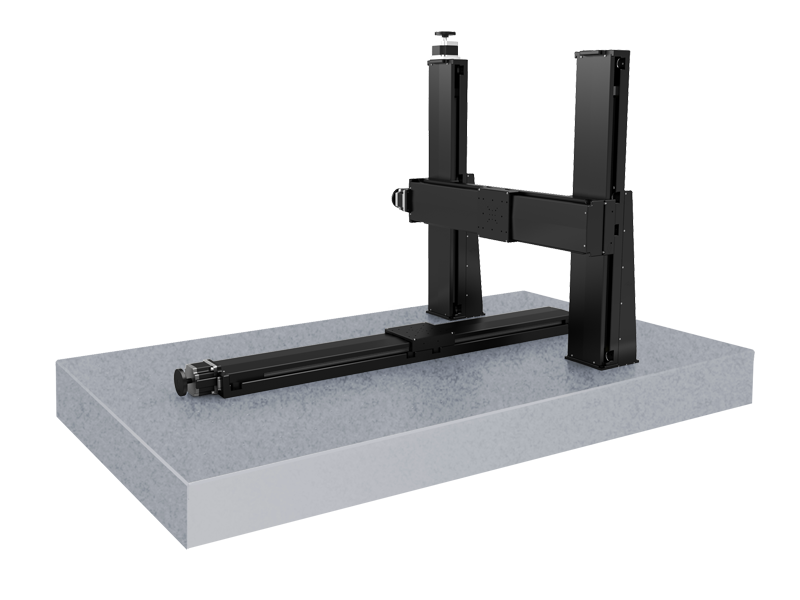

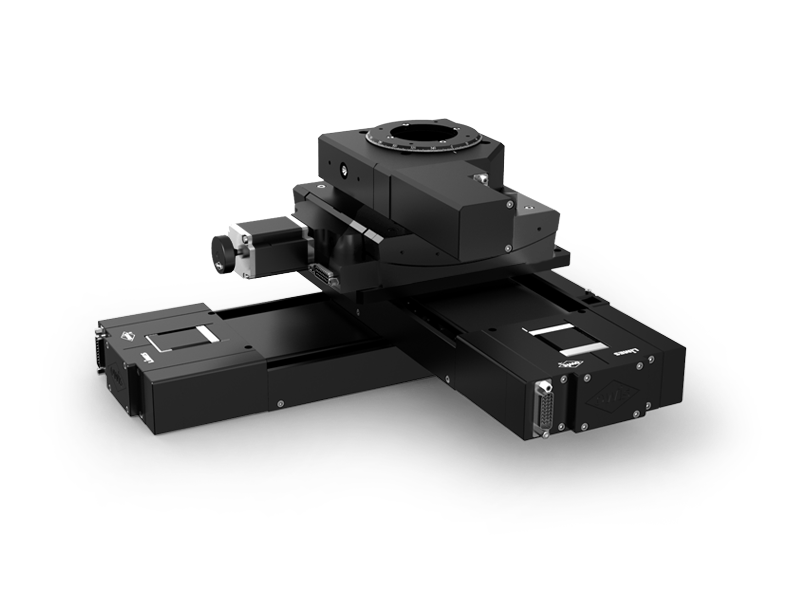

With the motorized high-precision linear stages of the LIMES series, we realize travels of up to 1,500 mm with minimal lateral and vertical runout. The repeatability is less than 2 µm. This makes high-precision measurement along the optical axis the standard!

EXAMPLES FROM PRACTICE

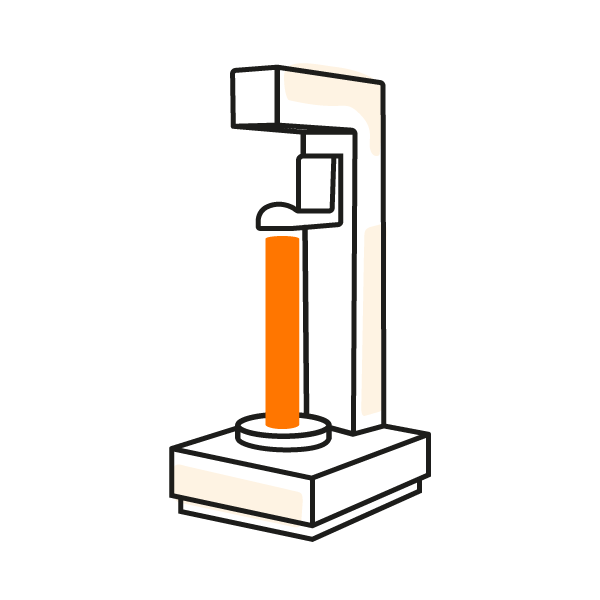

VERTICAL ALIGNMENT

The vertical alignment of the system allows space-saving superstructures. As an option and to protect your system, vertical structures can be secured with a motor holding brake. With our measuring equipment, we can measure and document all relevant properties of the entire system on request.

Application-specific combination options

Depending on the application, additional axes for positioning sensors and test objects, for example in the x-y direction or also goniometers, can be combined with the LIMES axes.

If your application cannot be fully mapped out with the OWIS components, we achieve this through application-specific adaptations and OEM solutions.

Typical applications:

- interferometer

- measurement of lenses

- alignment of laser systems