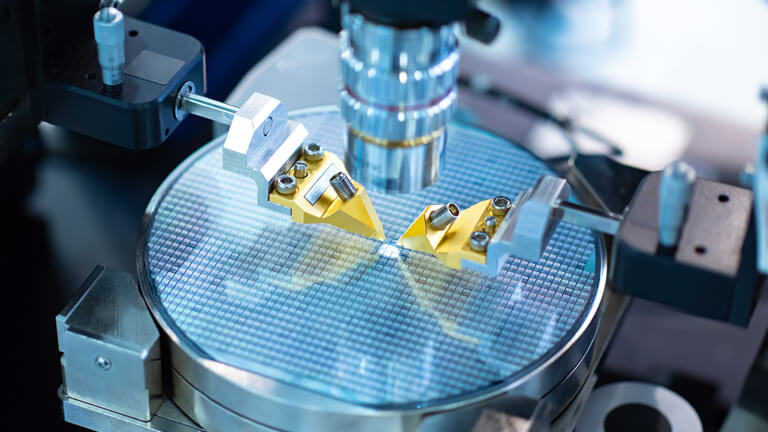

Made to meet semiconductors requirements

Customized positioning systems and OEM solutions

Due to their high precision and reliability, our components are perfect for use in semiconductor technology - in research, production and quality control.

With our 40 years of experience and OWIS Engineering, we adapt our positioning systems optimally to your requirements or develop an OEM solution specifically for your application. In doing so, we react very flexibly to your specific requirements.

Discover your possibilities

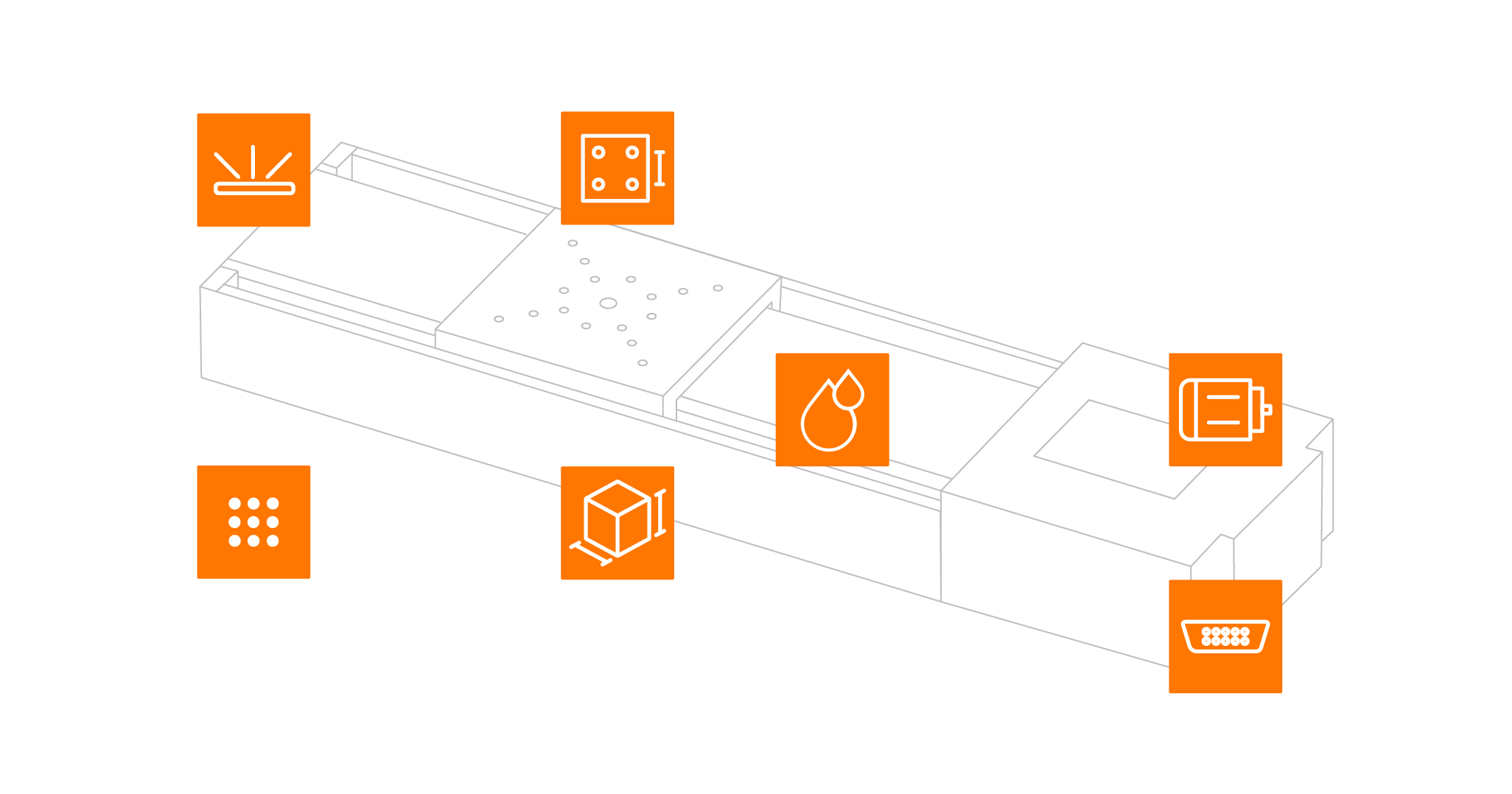

Customizing positioning stages and OEM solution for semiconductor manufacturing

Examples from practice – made by OWIS Engineering

Cleanroom compatible alignment and handling system, based on standard components

Features

- Based on OWIS linear und rotation stage

- Custom specific mounting pattern

- Nickel plated surface

- Vacuum compatible greases

OWIS guarantees

- Fast development

- High precision

- Proven and tested reliability

- Without any risks

This alignment and handling system shows how we modify our standard components for use in cleanrooms. More information on cleanroom-compatible products, such as manual and motorized positioners as well as beam guidance systems and optomechanical components, can be found in the product area.

What requirements should your cleanroom compatible alignment system meet?

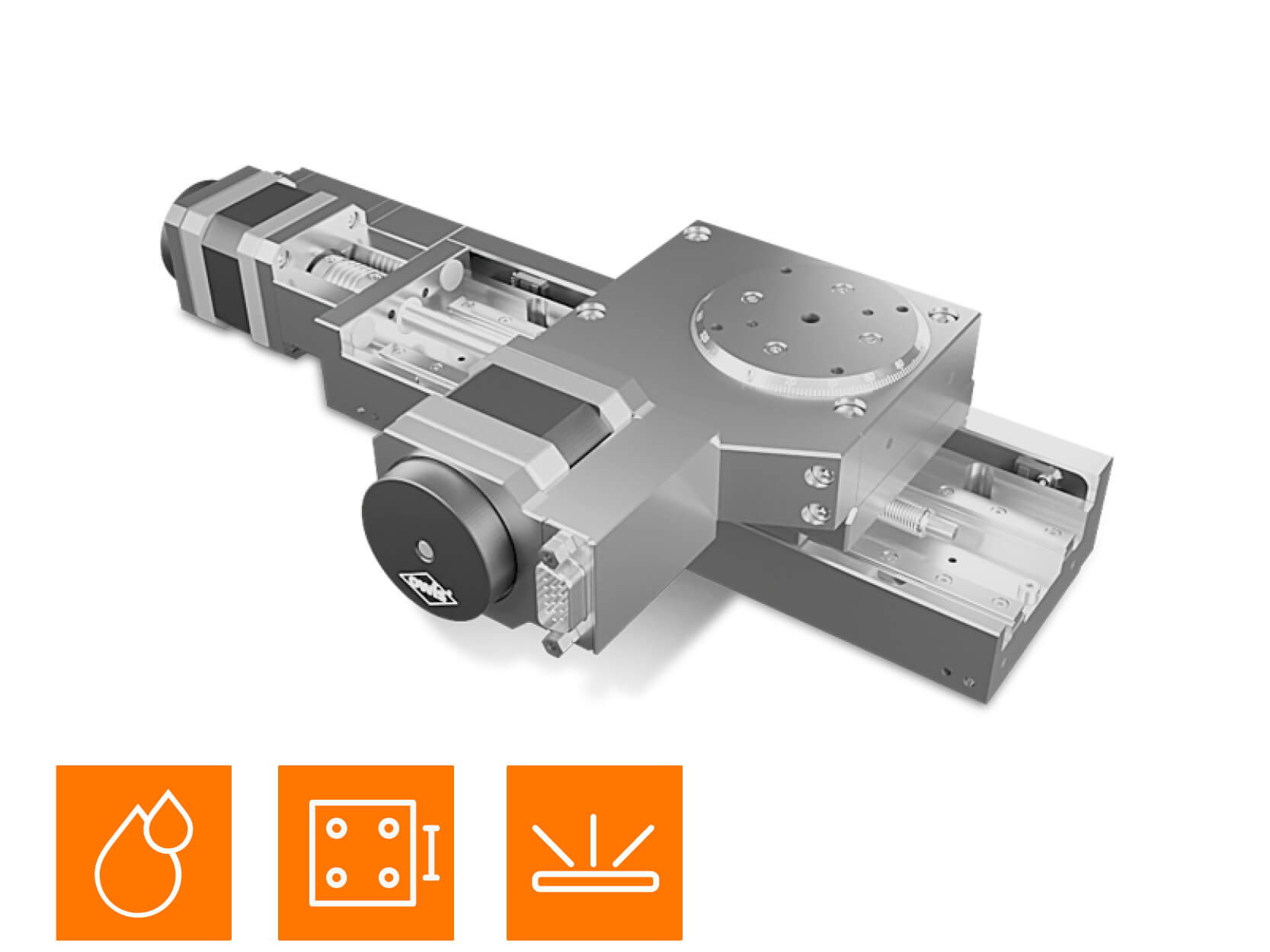

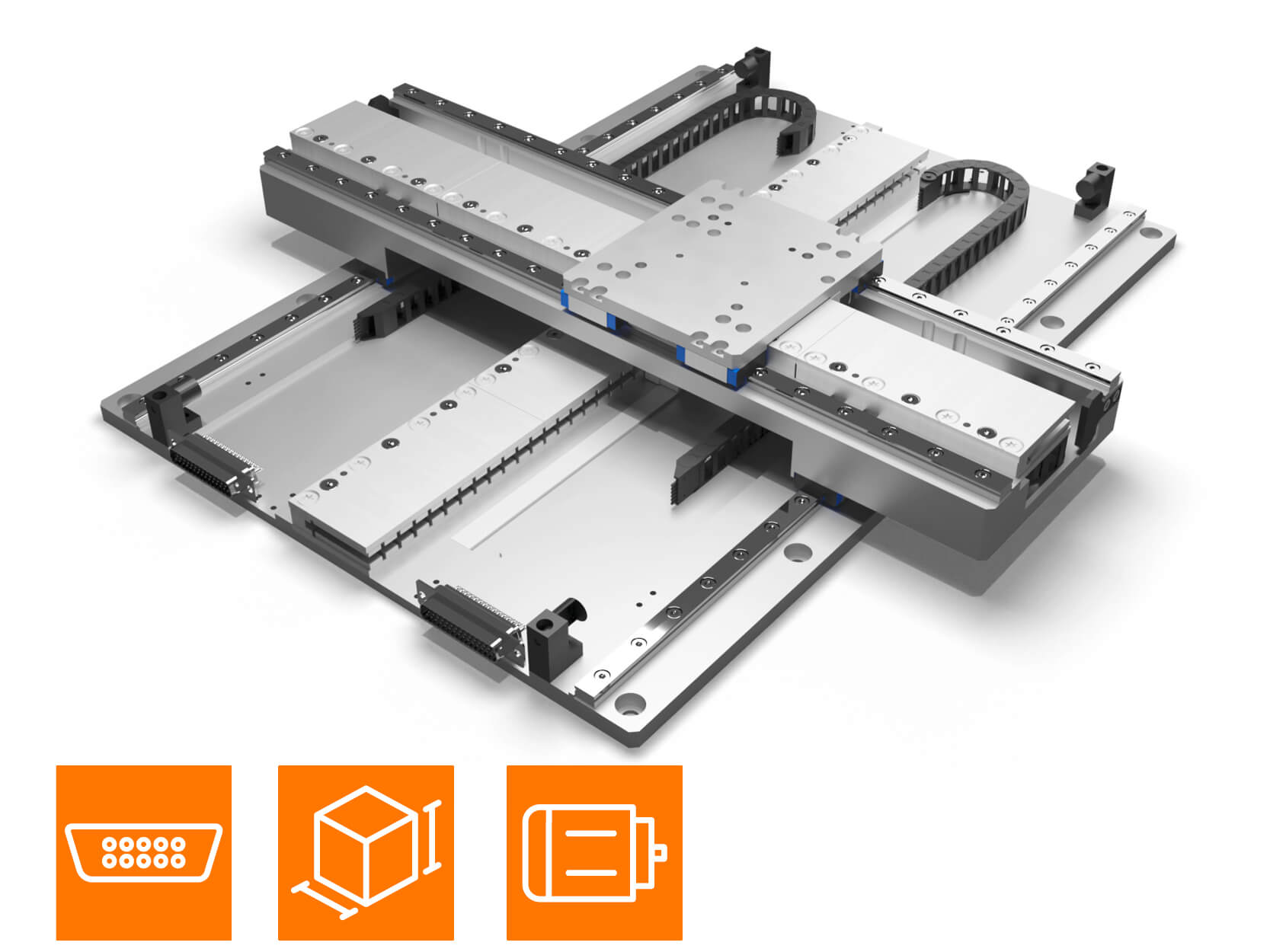

Cleanroom compatible, custom-designed scanning stage

Features

- Custom specific electrical connectors

- Fast direct driven motors

- minimized footprint for easy integration

OWIS guarantees

- Optimized performance

- Integration for customer equipment

- High precision

- Proven and tested reliability

This custom-designed scanning stage is just one example of how we develop OEM solutions for cleanroom applications with a high degree of individuality. With flexibility, we at OWIS Engineering are exactly the right partner for solutions in semiconductor production.

What are you planning and what are your requirements?

High flexibility and maximum of individualization – even for vacuum applications

Customized solutions for pressure ranges HV, UHV and XHV

Thanks to our own research and development department and our high vertical range of manufacture, we are also able to design our products for applications in high vacuum (HV), ultra high vacuum (UHV) and extremely high vacuum (XHV) environments. We assemble, test and measure your vacuum product in our cleanroom and ensure the product's suitability for UHV and XHV based on a residual gas analysis. Learn more about our vacuum compatible products or contact us to design your sprecific application.

What requirements should your vacuum-compatible component fulfill?

Curious? Challenge us!

-

Let us know about your application.

-

We check the feasibility.

-

We create an initial concept for your application.

Test us without obligation. Usually we create a first free concept and show you how we solve your requirements.

Get your free initial concept now.

Fill out the form and send it off. Dr. Johannes ter Wolbeek will contact you immediately and work with you to develop solutions for your requirements.