Semiconductor technology

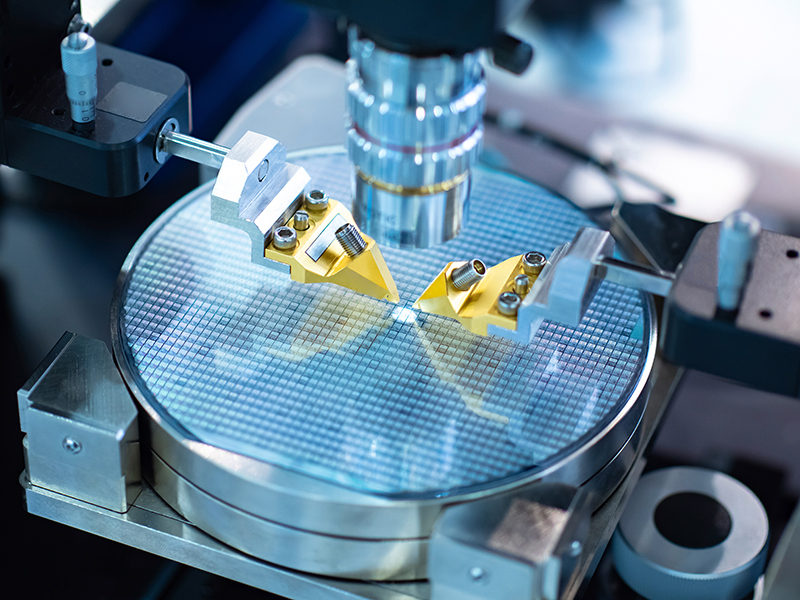

In the production and quality assurance of semiconductor products highly accurate and reliable positioning is a prerequisite.

With our 40 years of experience and OWIS Engineering, we combine our high-precision positioners into alignment and handling systems or develop OEM solutions, specifically for your application.

Thanks to our experience and know-how in the field of vacuum applications, we also implement your positioning requirements under cleanroom conditions.

7 scenarios for customizing components and solutions

OWIS components and solutions are made to meet semiconductors requirements. Not exclusively, of course… But there are actually a few reasons for this. Here are 7 scenarios how we customize our components and systems especially for the application in cleanroom conditions.

High precision positioners – also for cleanroom conditions

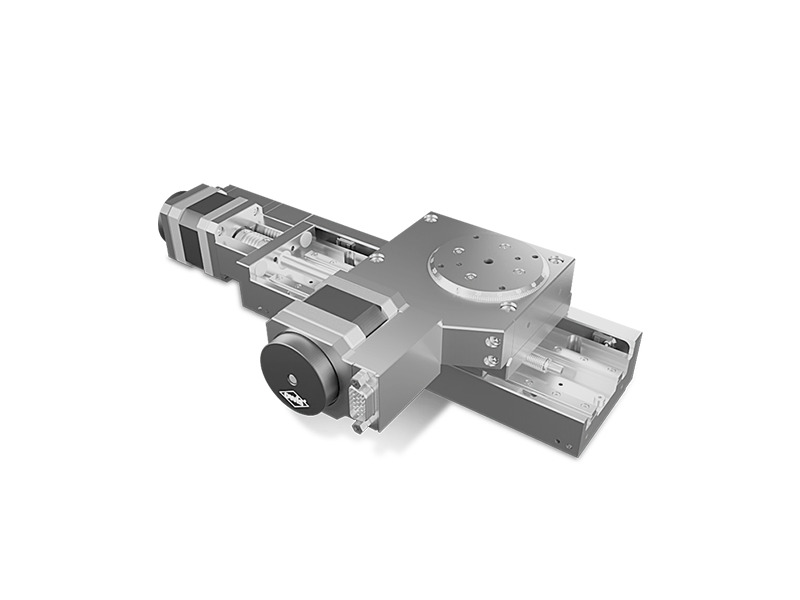

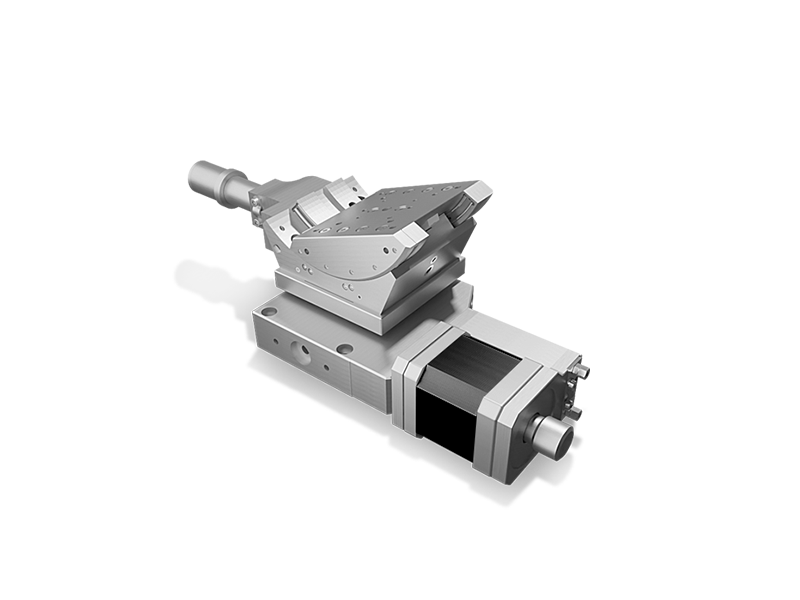

Our high-precision manual and motorized positioners provide the basis for high-resolution lithography and surface inspection in semiconductor technology. With our broad product portfolio, we cover linear and rotary directions of motion and realize the cleanroom compatible design of the positioners.

POSITIONING SYSTEMS FOR CLEAN ROOMs – MADE BY OWIS ENGINEERING

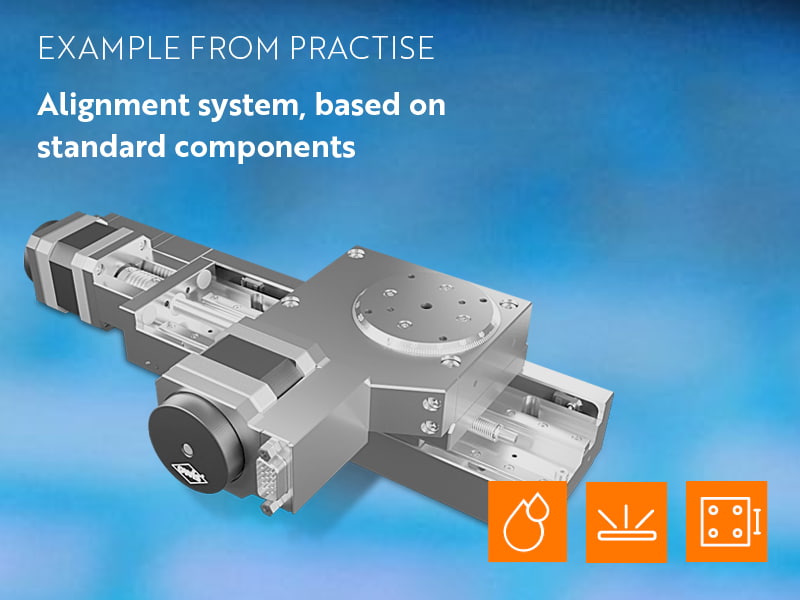

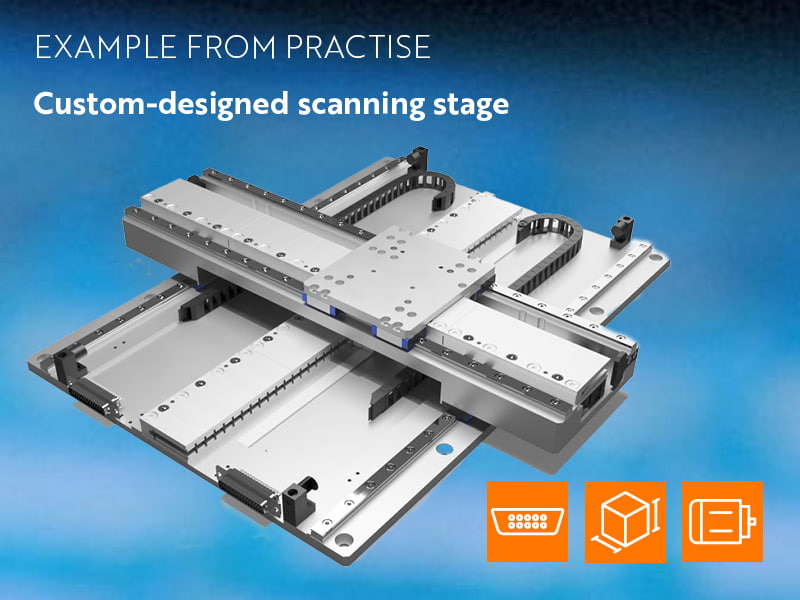

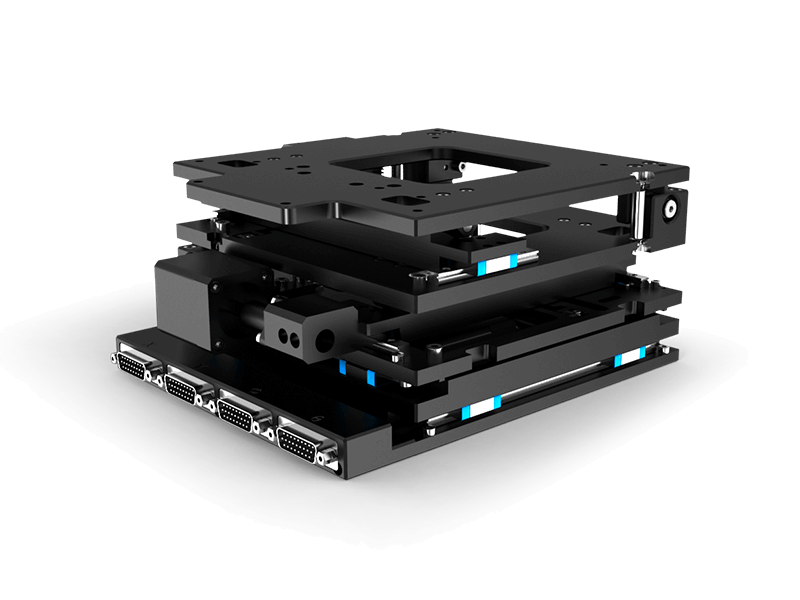

With OWIS Engineering we build OEM solutions or combine our high precision positioners to individual alignment and handling systems, for example for X-ray spectroscopy and ellipsometry. Thanks to our vacuum expertise, we realize these highly accurate and reliable plug-and-play systems also for cleanroom applications.

Which design are you planning?

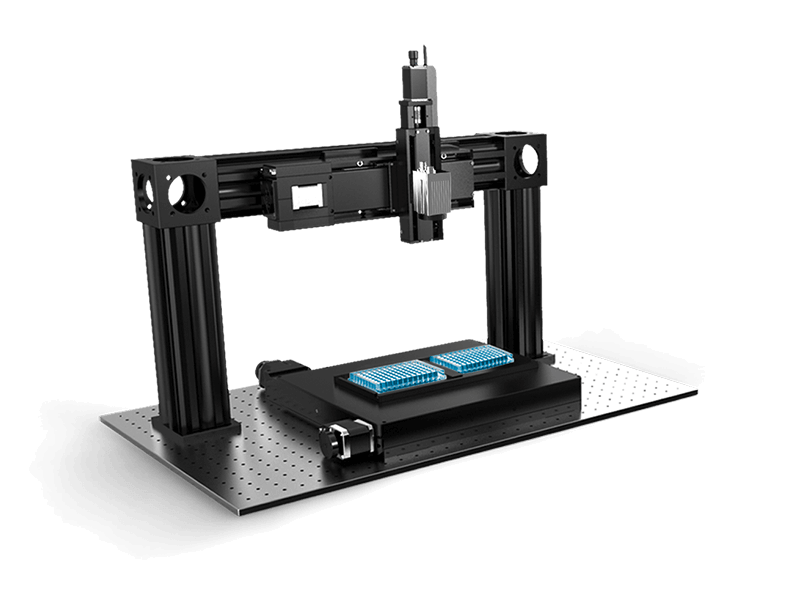

Positioning systems or gantry solutions: Both are typical applications which we realize for you with OWIS Engineering. From application-specific design to on-time delivery.