Positioners and optomechanical components adapted for use in cleanrooms

With our know-how and experience from the vacuum sector, we are able to make all our standard components fit for cleanroom applications. We adapt our products to industry-specific requirements with various surface finishes. Finally, assembly takes place in our own clean room. Here we lubricate the cleanroom-compatible products with the required greases.

Let's talk about your application in your cleanroom and customize your specific product.

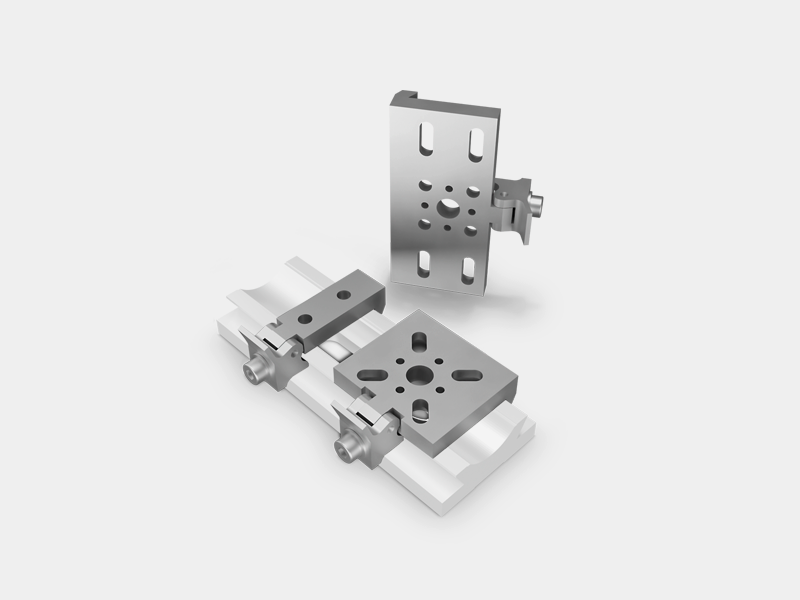

contact usCleanroom compatible beam handling systems

With our modular system of beam handling components and systems, optical experiments can be set up easily, quickly and individually and carried out at different beam heights. Let's talk about adapting your beam handling systems to meet cleanroom requirements.

Selected examples

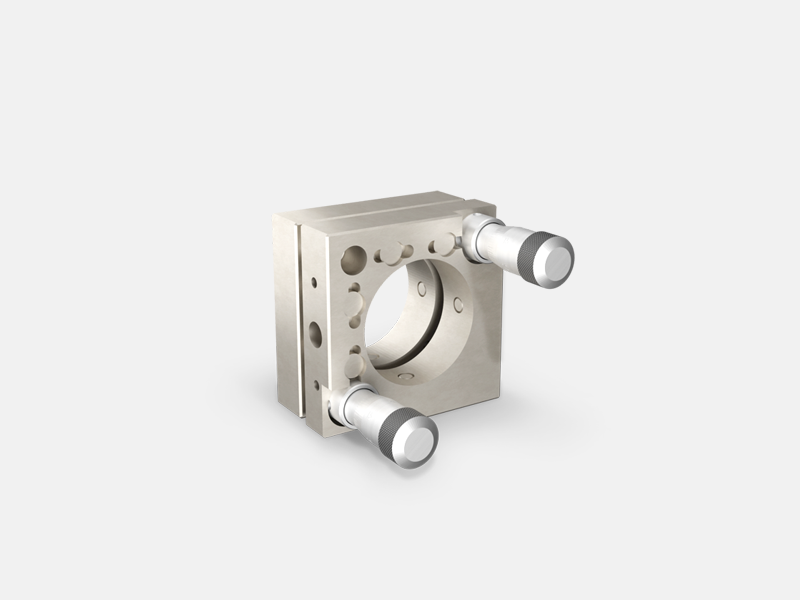

Cleanroom compatible optomechnical components

High-precision mounts and adjustment units for optical elements such as lenses, filters, mirrors and shutters. Let's talk about adapting your optomechnical components to meet cleanroom requirements.

Selected example

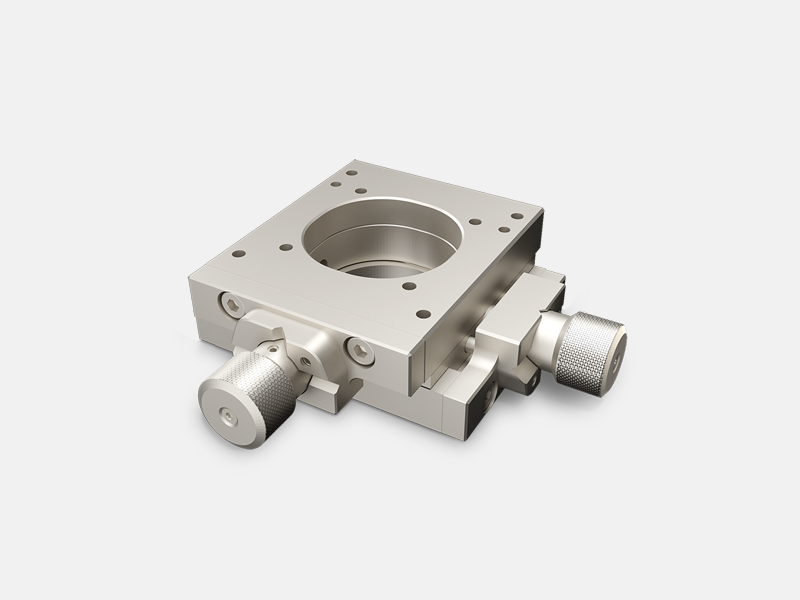

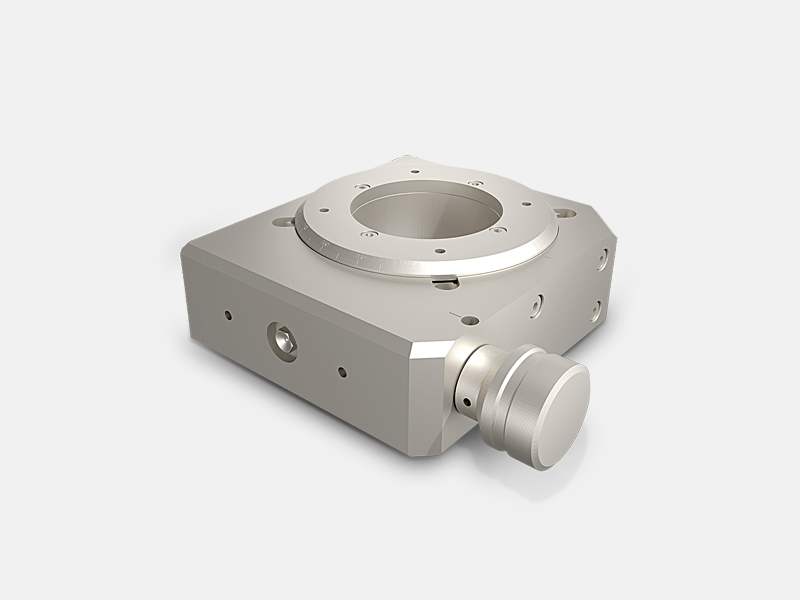

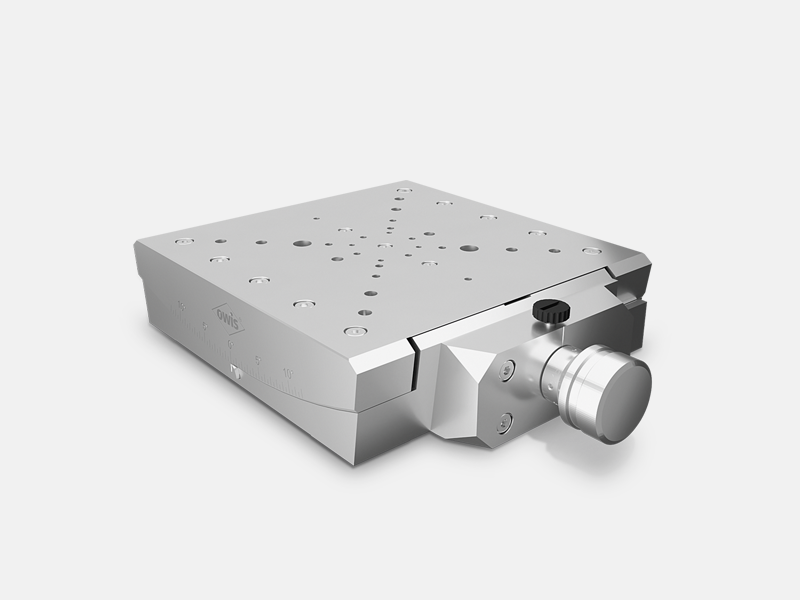

Cleanroom compatible manual positioners

Precise motion sequences and a wide range of possible combinations of linear, rotary and swivel axes. Let's talk about adapting your manual positioners to meet cleanroom requirements.

Selected examples

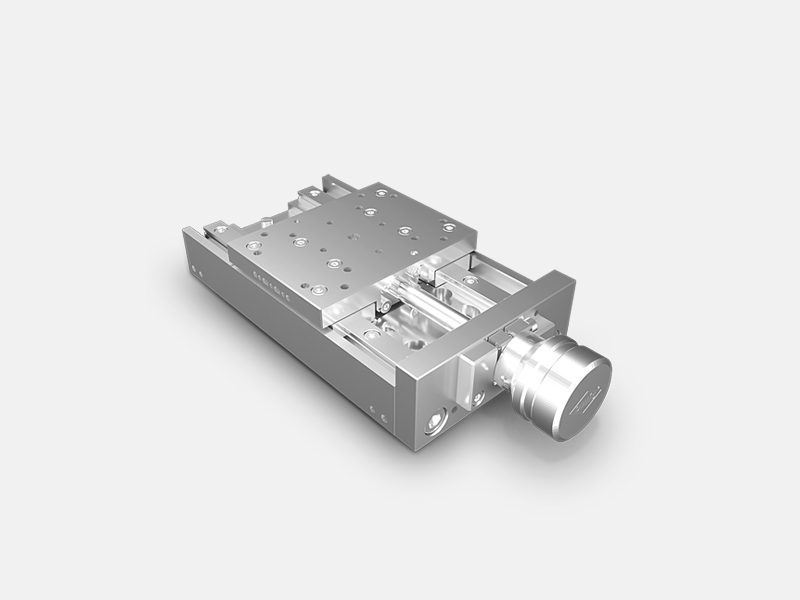

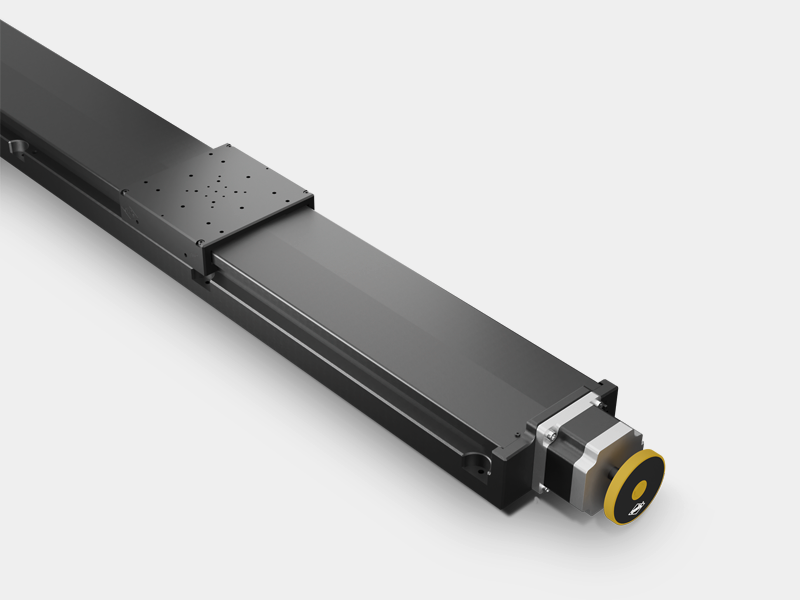

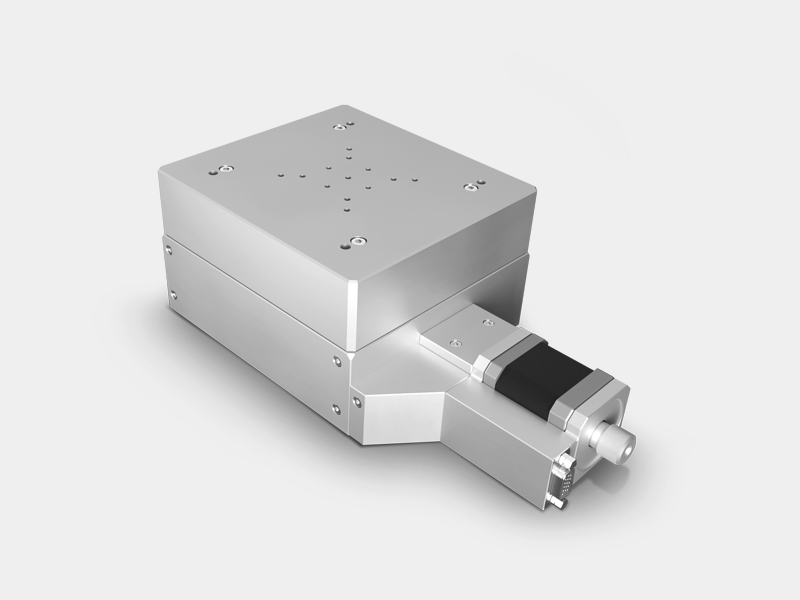

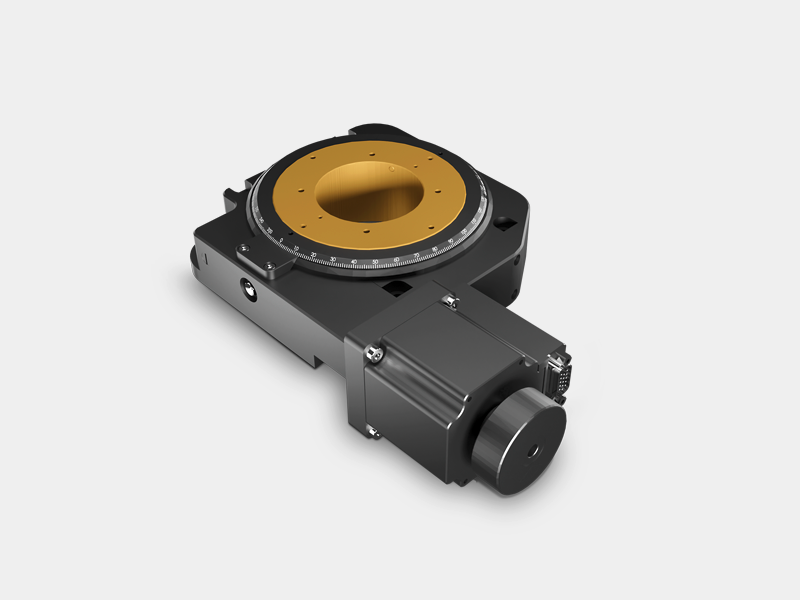

Cleanroom compatible motorized positioners

Highly precise linear, rotary and swivel axes for high-accuracy alignment and handling tasks in research and industry. Let's talk about adapting your motorized positioners to meet cleanroom requirements.

Selected examples

Customizing for applications in cleanrooms

Every cleanroom setup has its own challenges. We would be happy to support you with OWIS Engineering and work with you to find the right solution for your application.