Our competencies are the basis for making groundbreaking ideas a reality.

We at OWIS have a unique set-up. Competent and experienced, we develop solutions to individual challenges. Flexible and powerful, we react to specific requirements and put them into practice with a high degree of vertical integration and quality. This also applies to applications under vacuum and cleanroom conditions.

Convince yourself of our competences and challenge us!

Consulting: Allies of your idea.

In consulting, we bring our know-how and experience to support you in selecting the ideal product or the appropriate technology – tailored to your application.

With our expertise and in combination with our broad product portfolio, we make individual adjustments to standard components or develop OEM solutions. Together with you. Always at eye level, always in the sense of the application and always in the highest quality.

"As an ally of your idea we find the best possible positioning or beam guiding solution. Flexible, tailored and with a convincing result."

Dr. Dominik Zimmermann

Team engineering

Development: Turning ideas into solutions.

When it comes to transforming groundbreaking ideas into beam guiding and positioning systems, we put our many years of development experience to work for your benefit. In direct contact with you and with knowledge of your individual requirements, we see ourselves as a praxis-oriented development partner.

The different specializations in our development team form a very broad knowledge and experience base. In combination with our manufacturing and assembly competence, we design with a view to feasibility and efficiency.

"Due to the proximity to market and application, we are the perfect development partner for your individual solution."

Dr. Peter Hilgers

Team development

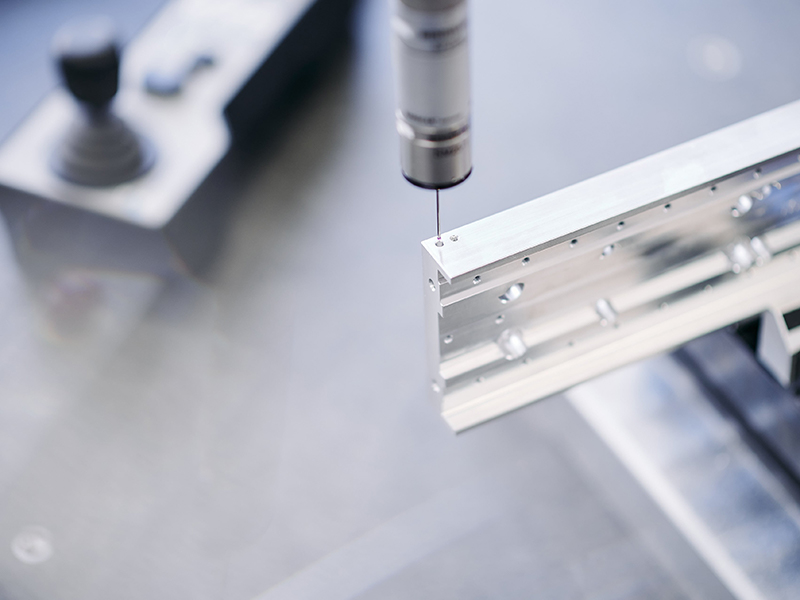

Manufacturing: Shaping with micrometer accuracy.

With our own CNC production at the company site in Staufen, we produce the required components in-house – with high precision and in the micrometer range. Thanks to our experienced manufacturing team and state-of-the-art CNC machining equipment, we respond quickly and flexibly to customer-specific requirements and give shape to groundbreaking ideas.

To ensure the high OWIS quality, we have the necessary equipment and know-how. Our constant and very conscientious quality controls are an essential part of our value creation process. At the same time, we are working on the continuous development and optimization of our processes. So that you can continue to rely on our products and engineering services in the future.

"We manufacture all required parts in-house on our state-of-the-art CNC machines. In doing so, we are fast, precise and can react very flexibly to special requirements."

Aleks Sterz

Team manufacturing

"The continuous development and optimization of our processes improves our efficiency and results in a very high quality of our products."

Fabian Giesin

Team process development

Assembly: bringing solutions to life.

When assembling highly sensitive components, everything has to be perfect. Tools, cleanliness and care. Our experienced assembly team works conscientiously at state-of-the-art workstations and has high-quality tools and testing equipment at its disposal. In this way, we refine the upstream added value and bring reliable and high-quality standard and special products as well as entire subsystems to life.

To ensure the requested product performance data, we carry out the measurement on the interferometer ourselves.

"I bring in my know-how and my experience when mounting the highly sensible components."

Kathrin Zöller

Team assembly

"After assembly, we use interferometric measurement to ensure that our products meet the required performance data."

Stefan Schmidt

Team assembly

Cleanroom: Refining solutions.

For cleanroom applications, we design our manual and motorized positioners as well as beam delivery systems and optomechanical components specifically for the application in accordance with the requirements.

With our know-how and experience from the vacuum area, we are able to select the appropriate standard component in every case and make it fit for the clean room. Starting with the cleaning of the components, through assembly to the measurement of the products and solutions.

"By avoiding particle contamination during assembly and measurement, we ensure that our products meet your requirements for vacuum and cleanroom applications."

Stefan Schmidt

Team assembly

Vacuum: Qualifying solutions for underpressure

Due to our long-standing cooperation with renowned research institutes, we have today established an outstanding position for applications in vacuum. This enables us to design our products and components for applications in HV, UHV ranges and, since 2019, also in XHV ranges. In design, we are able to implement application-specific requirements.

We assemble, test and measure your vacuum product in our clean room (ISO 5) and ensure the suitability of the products for UHV and XHV by means of a residual gas analysis.

"With our research and development work, we have developed outstanding expertise in the field of vacuum."

Dr. Johannes ter Wolbeek

Team vacuum and cleanroom